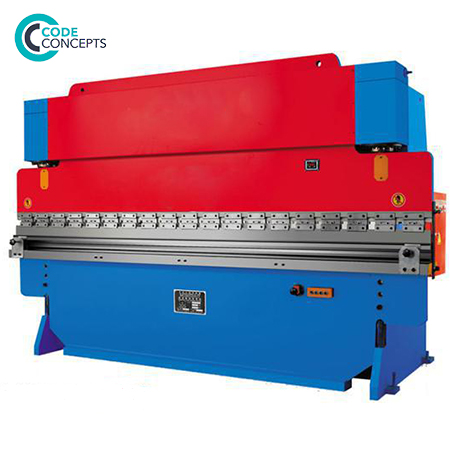

Hydraulic Press Brake

Technical Specifications

Model WC67Y

100T/2500

100T/3200

160T/3200

160T/4000

Nominal Pressure

1000 kN

1000 kN

1600 kN

1600 kN

Worktable Length

2500 mm

3200mm

3200mm

4000mm

Distance between

panels

1900 N/mm²

2600 N/mm²

2600 N/mm²

3400 N/mm²

Throat Depth

300 mm

300 mm

340 mm

340 mm

Slide Stroke

140 mm

140 mm

200 mm

180 mm

Max Opening Height

390 mm

390 mm

440 mm

440 mm

Slider Stroke Speed

70 No load

8 work

60 return

70 No load

8 work

60 return

70 No load

8 work

60 return

70 No load

8 work

60 return

Main Motor Power

7.5 KW

7.5 KW

11 KW

11 KW

Overall Dimension

2.9×1.7×2.5 m

3.3×1.7×2.5 m

3.7×1.9×2.7 m

4.5×1.9×2.8 m

Model WC67Y 200T/3200,300T/4000

Model WC67Y

200T/3200

300T/4000

Nominal Pressure

2000 kN

3000 kN

Worktable Length

3200mm

4000mm

Distance between

panels

2500 N/mm²

3300 N/mm²

Throat Depth

360 mm

400 mm

Slide Stroke

200 mm

250 mm

Max Opening Height

480 mm

540 mm

Slider Stroke Speed

60 No load

8 work

50 return

60 No load

6 work

50 return

Main Motor Power

22 KW

22 KW

Overall Dimension

3.7×2.2×2.9 m

4.5×2.5×3.65 m

Main Structure

1. Frame part:

WC67Y Series hydraulic press brake machine adopts hydraulic driven, frame part includes ram, cylinder and mechanical chock block micro-metric setting. The length of ram travel can be regulated arbitrarily, if the bent workpiece unnecessary with too long travel, will adjust travel by mechanical chock block, thus higher work efficiency obvious. The left and right cylinders are fixed upon the frame, let piston to driven ram lift up and down by the hydraulic system.

2. Worktable part:

Installed four compensation cylinder in vertical sheet plate of the worktable, can to reach better press brake performance. To control worktable by the button in the front of the worktable, let motor-driven stock frame-level move, and logical display the movement, installed position switches at the front and back limit stations.

3. Slider part:

Slider part is composed of the slider, cylinder and mechanical block fine-tuning device. It adopts overall panel structure, left and the right cylinder is fixed on the machine frame, through a hydraulic piston (rod) driven slider doing up and down movement.

4. Synchronous system:

The synchronous construction of this device composed of twist shaft, swing beam, this structure is simple, performance is reliable and steady, synchronous accuracy is high.

5. Back gauge Device:

Manipulated by the button box before the working table, make the motor-driven gauge frame moving, and has moving distance digital display, the minimum reading of 0.10 mm. Front and back position both have stroke limit switch.

6. Accuracy compensation mechanism:

The fine-tuning mechanism is installed on the upper mould, used for up and down compensation fine-tuning, in order to guarantee the bending accuracy. Sometimes, when bending, the angle degree in the total length has a slight deviation, in order to get the consistency of the bending angle degree, you can loose the screw, move the Oblique block, then doing fine-tuning on the upper mould, then tighten the screw, re-bending till meet your requirement.

7. Electric System:

Main Power supply: 380V, 50Hz, three-phase,

Control power supply: 220V 24V.

The main circuit and the motors are using automatic switching circuit and overload protection. The control loop sections are using the short-circuit protection fuse. The main mechanical components are grounded.

The machine has three ways of working, by the universal switch SA3 to select jog, single, continuous.

Machine operation is controlled by a footswitch, convenient and fast.

Electric components are the Siemens brand.

The line is simple, safe and easy to maintenance.

8. Hydraulic System:

The hydraulic system consists of a motor, axial piston pump, valve, fuel tank, fuel lines and hydraulic accessories.

The maximum working pressure of the hydraulic system is 25MPa, set through the main loop system valve.

Contact Us

Tel: +91-9600881584

Email: [email protected]